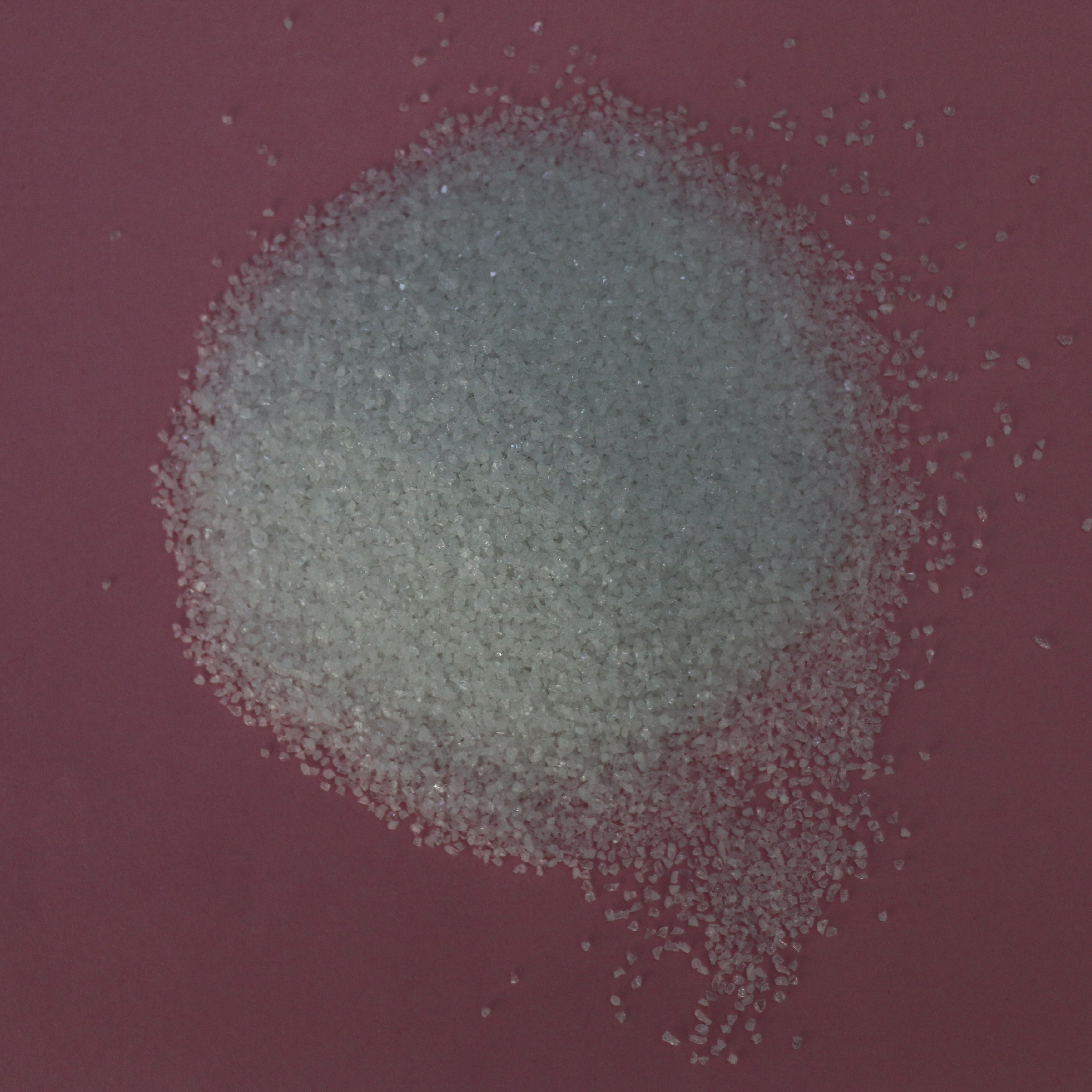

Cov duab ntawm cov khoom superabrasive thiab cov txheej txheem ntawm cov txheej txheem ua lub luag haujlwm tseem ceeb hauv kev sib tsoo lub log rau ntau yam kev siv.

Sib piv daim ntawv thov mus rau qhov zoo tshaj plaws superabrasive log tuaj yeem tau txais txiaj ntsig los ntawm kev txhim kho qhov zoo thiab cov khoom lag luam tawm los, ua rau qhov kev paub tob ntawm grit, daim ntawv cog lus thiab txheej txheej tseem ceeb rau cov neeg siv khoom sib tsoo.Duab los ntawm Wanyu Abrasives.

Txoj kev xaiv ntawm super nyuaj sib tsoo log yog qhov tseem ceeb rau kev sib tsoo kom zoo.Lub log txoj cai tuaj yeem txhim kho qhov chaw hauv ib teev, txo cov cuab yeej hloov pauv, ua kom lub sijhawm ua haujlwm ntawm lub tshuab, txhim kho cov khoom zoo thiab txo cov nqi khiav lag luam.Txawm li cas los xij, nrhiav lub log zoo li no yuav tsum tau ua tib zoo kawm txog cov khoom zoo ntawm cov nplej thiab cov txheej txheem superabrasive, nrog rau lwm cov yam ntxwv.

Superabrasive sib tsoo lub log ua haujlwm nyob rau hauv kev sib tsoo hnyav thiab yuav tsum muaj ntau yam khoom, suav nrog hardness ntawm qhov kub thiab txias, siab thermal conductivity kom tshem tawm cov cua sov los ntawm kev txiav ntug, muaj kev ruaj khov, hnav tsis kam, lubrication thiab tsis kam rau cov yas deformation.

Qhov kev ua tau zoo ntawm lub log sib tsoo superabrasive feem ntau yog txiav txim siab los ntawm kev sib koom ua ke, nrog rau cov yam ntxwv ntawm lub hauv paus thiab qhov zoo ntawm cov pob zeb abrasive ntawm lub log, yog pob zeb diamond lossis cubic boron nitride (CBN).Cov khoom sib txawv thiab cov txheej txheem sib txawv muab lub zog sib txawv thiab yog li tsim nyog rau kev siv sib txawv.Paub tias cov khoom thiab cov txheej txheem twg yog qhov zoo tshaj plaws rau cov ntawv thov tshwj xeeb tuaj yeem txuag cov tuam txhab nyiaj hauv lub sijhawm.

Nyob ntawm daim ntawv thov lossis cov txheej txheem sib tsoo, cov nplej hwm lossis cov nplej kim dua yuav yog qhov kev xaiv pheej yig tshaj plaws rau txoj haujlwm.Ib yam li ntawd, cov pob zeb diamond kim tshaj plaws lossis CBN lub log yuav tsis haum rau daim ntawv thov.Dab tsi tseem ceeb tsis yog tus nqi, tab sis cov duab ntawm cov nplej superabrasive thiab hom txheej siv ntawm lub log.

Toughness yog hais txog tus cwj pwm ntawm abrasive grain nyob rau hauv mechanical kev nyuaj siab, uas yog, nws muaj peev xwm tiv thaiv cracking, chipping, thiab tawg.Brittleness yog hais txog lub peev xwm ntawm cov nplej kom tawg thiab nws tus kheej ntse.

Nyuaj super abrasive nplej zoo li clumpy thiab tuav lawv cov duab zoo dua li lawv tshem tawm cov khoom.Brittle hais yog ib ntus sharpened, lawv cov duab angular tshem tawm ntau cov ntaub ntawv nrog txhua kis.Cov ntawv thov sib txawv xav tau cov nplej ntawm cov ntsiab lus sib txawv ntawm cov spectrum ntawm ob daim ntawv no.

Nyob rau hauv cov nqe lus ntawm daim ntawv, muaj ob tug polar pawg: blocky thiab angular.Qhov ntau agglomerated los yog sib npaug ntawm cov khoom abrasive, qhov tsawg dua qhov kev txiav, tab sis qhov zoo dua qhov zoo yog khaws cia.Cov khoom clumped muaj zog dua thiab tiv taus ntau dua abrasive rog ua ntej tawg.

Conversely, angular shapes yog nruj dua thiab zoo dua nkag mus thiab tshem tawm cov khoom.Txawm li cas los xij, angular nplej raug rhuav tshem nrog kev siv zog tsawg dua.

Qhov zoo tshaj plaws, yuav tsum muaj qhov sib npaug uas sib npaug ntawm ob daim duab, tso cai rau nws nyob ruaj khov, tso cai rau nws ua kom tawg, nthuav tawm qhov tshiab, ntse txiav.Yog tias tsis muaj peev xwm ua kom tawg, cov nplej yuav npub thiab rub tawm ntawm lub workpiece es tsis txhob txiav, ua rau muaj kev sib tsoo quab yuam thiab teeb meem loj rau lub log thiab workpiece.

Txheej yog txheej txheem ntawm tag nrho thiab uniformly txheej superabrasive nplej nrog ib txheej ntawm cov khoom ntxiv.Cov txheej txheem no ua kom cov nplej loj thiab qhov hnyav, uas feem ntau siv los txhim kho cov khoom zoo xws li lub zog thiab ua haujlwm ntev hauv kev sib tsoo.

Lub zog ntawm kev sib raug zoo matrix los tuav cov nplej abrasive txiav txim siab qhov ua tau zoo ntawm lub log sib tsoo.Lub ntsiab kom zoo dua ntawm cov coatings yog hais tias lawv muaj peev xwm ua kom zoo nkauj lub pob zeb diamond los yog CBN hais kom zoo dua nyob rau hauv lub log, yog nws resin, vitreous, hlau, hybrid los yog lwm yam.Txhim kho txhua yam thiab tshuaj khaws cia ntawm kev sib koom ua ke txhim kho lub log kev ncaj ncees.

Kev txuag nqi thiab kev tsim khoom siab tshaj plaws uas tuaj nrog xaiv txoj kev sib tsoo log tuaj yeem yooj yim dhau los ua kev sib tw kom zoo dua yog tias lub rooj cob qhia ua nws daim npav zoo.

Nickel, tooj liab thiab nyiaj coatings yog cov feem ntau superabrasive txheej.Nickel plating yog muaj nyob rau hauv resin bonded log.Cov coatings no txhim kho lub neej ntawm lub log, nto tiav, tshav kub dissipation thiab mechanical adhesion rau kev sib txuas ntawm qhov chaw kom ua tau zoo tshaj plaws.

Copper coatings yog txheej txheej ntawm kev xaiv rau kev sib tsoo qhuav vim muaj peev xwm ntawm tooj liab los ua kom sov deb ntawm qhov chaw sib tsoo thiab txhim kho kev tuav ntawm cov khoom siv thiab tshuaj lom neeg hauv kev sib koom ua ke.

Cov xim nyiaj yog kim dua tab sis muab cov thermal conductivity siab tshaj plaws ntawm peb txheej txheej, nrog rau kev txhim kho cov khoom khaws cia thiab ntxiv lubricity.Silver yog qhov zoo tshaj plaws tiav thaum cov roj ntshiab siv los ua lub coolant.

Tus nqi ntawm txheej ntawm cov nplej abrasive tuaj yeem yog los ntawm 30% mus rau 70% ntawm tag nrho qhov hnyav ntawm cov nplej coated.Txheej ntawm pob zeb diamond hais feem ntau yog 50% mus rau 56% los ntawm qhov hnyav, thaum CBN hais feem ntau siv rau txheej txheej ntawm 60% los ntawm qhov hnyav.Coated superabrasives zoo li yuav kim dua li cov tsis muaj coated abrasives vim lawv qhov kev xav tau siab dua thiab cov txheej txheem tsim khoom ntxiv yuav tsum tau ua.

Txawm tias me me kev hloov kho rau lub abrasive nyob rau hauv lub sib tsoo log yuav ua tau ib tug game changer rau koj sib tsoo system thiab txheej txheem.Kev txuag nqi thiab kev tsim khoom tau txais txiaj ntsig los ntawm kev xaiv txoj kev sib tsoo log tuaj yeem yooj yim dhau los ua kev sib tw kom zoo dua yog tias lub rooj cob qhia plays nws daim npav txoj cai.

Los ntawm kev siv cov txheej txheem kev ua haujlwm siab, kev ua haujlwm siab milling hauv kev ua haujlwm machining, SolidCAM iMachining thev naus laus zis tuaj yeem txo lub sijhawm voj voog thiab ua kom lub neej muaj txiaj ntsig zoo piv rau cov tsoos milling.

Cov rog uas koom nrog hauv cov txheej txheem milling tuaj yeem suav tau, tso cai rau cov cuab yeej siv lej siv los kwv yees thiab tswj cov rog no.Cov qauv qhia meej rau kev suav cov rog no tso cai rau koj los ua kom zoo dua ntawm kev ua haujlwm milling.

Post lub sij hawm: Apr-23-2023