Chrome corundum (tseem hu ua liab corundum) yog tsim los ntawm cov tshuaj tiv thaiv ntawm metallurgical chrome-ntsuab thiab muaj alumina ntawm qhov kub siab tshaj 2000 degrees.Ib qho nyiaj ntawm chromium oxide ntxiv thaum lub sij hawm smelting, uas yog lub teeb liab los yog sawv.

Chromium corundum excels nyob rau hauv kev ua tau zoo nrog rau siab hardness, siab toughness, siab purity, zoo heev tus kheej-sharpening, muaj zog sib tsoo muaj peev xwm, tsawg tshav kub tiam, high efficiency, acid thiab alkali tsis kam, kub tsis kam, thiab thermal stability.

Qhov sib ntxiv ntawm cov khoom siv tshuaj Cr hauv chrome corundum txhim kho qhov toughness ntawm nws cov cuab yeej abrasive.Nws zoo ib yam li dawb corundum hauv hardness tab sis siab dua hauv toughness.Cov cuab yeej abrasive ua los ntawm chrome corundum muaj qhov ua haujlwm zoo thiab ua tiav siab.Nws yog dav siv nyob rau hauv abrading, sib tsoo, polishing, precisely casting xuab zeb, txau cov ntaub ntawv, tshuaj catalyst cab kuj, tshwj xeeb ceramics thiab hais txog.Cov teb uas siv tau muaj xws li: ntsuas cov cuab yeej, cov cuab yeej siv tshuab spindles, ntsuas qhov chaw, kev sib tsoo meej hauv threaded ntau lawm thiab qauv.

chrome corundum muaj viscosity siab thiab zoo permeability vim yog chromium oxide-muaj iav tivthaiv, uas tuaj yeem tiv thaiv kev yaig thiab nkag mus ntawm molten slag.Nws kuj tau dav siv nyob rau hauv qhov kub thiab txias teb nrog hnyav ib puag ncig, nrog rau cov uas tsis yog-ferrous metallurgy furnaces, iav melting furnaces, carbon dub reactors, khib nyiab incinerators thiab refractory castables.

Chromium corundum khoom

Lub cev thiab tshuaj ntsuas ntsuas

| Cov ntsiab lus ntawm chromium oxide | Tsawg chrome 0.2-0.45 Nws | Cov chromium 0.45—1.0 Nws | Siab chromium 1.0-2.0 Nws |

Granularity ntau yam

| AL2O3 | Na2O | Fe2O 3 | |

| F12-F80 | 98.20 mn ib | 0.50 max | 0.08 max |

| F90-F150 | 9 8.50mn | 0.55 max | 0.08 max |

| F180-F220 | 98.00 Nws | 0.60 max | 0.08 max |

Muaj tseeb ceev: 3.90g / cm3 Qhov ceev: 1.40-1.91g / cm3

Microhardness: 2200-2300g / hli

Chrome Corundum Macro

| PEB | Qhov nruab nrab grain loj (μm) |

| f020 ua | 850-1180 : kuv |

| f022 ua | 710-1000 Nws |

| f024 ua | 600-850 Nws |

| f030 ua | 500-710 Ib |

| f036 ua | 425-600 Nws |

| f040 ua | 355-500 ib |

| f046 ua | 300-425 : kuv |

| f054 ua | 250-355 : kuv |

| f060 ua | 212-300 : kuv |

| f070 ua | 180-250 Nws |

| f080 ua | 150-212 : kuv |

| f090 ua | 125-180 : kuv |

| F 100 | 106-150 : kuv |

| F 120 | 90-125 : kuv |

| F 150 | 63-106 : kuv |

| F 180 | 53-90 : kuv |

| F 220 | 45-75 : kuv |

| F240 | 28–34 : kuv |

Tej yam kev soj ntsuam lub cev

| Al2O3 | 99.50% |

| Cr2O 3 | 0.15% |

| Na2O | 0.15% |

| Fe2O 3 | 0.05% |

| CaO | 0.05% |

Cov yam ntxwv ntawm lub cev

| Hardness | 9, 0 hmu |

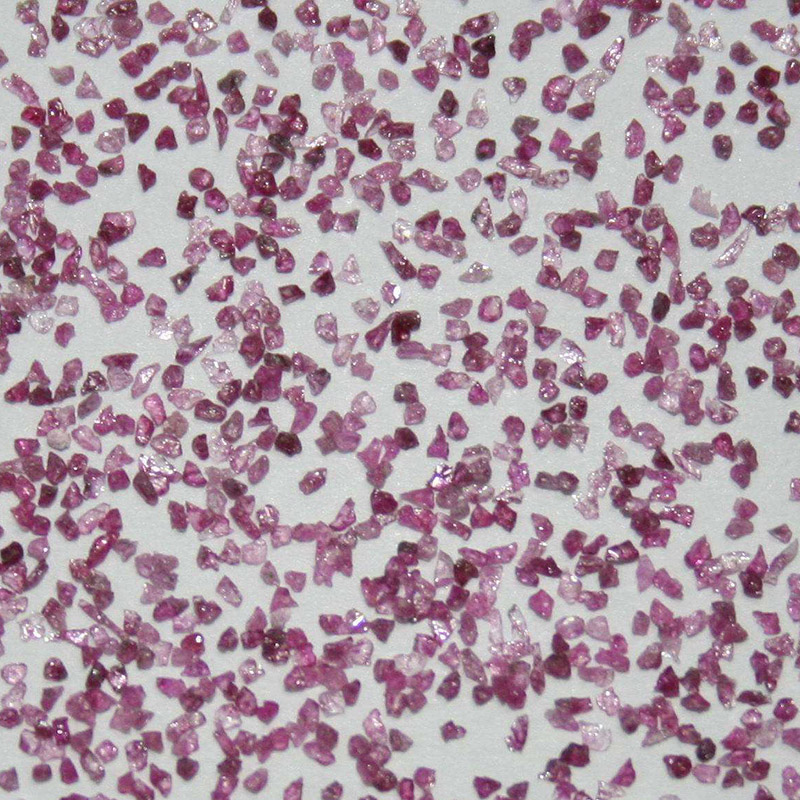

| Color | liab |

| Cov qoob loo | lub kaum sab xis |

| Melting point | ca.2250 ° C |

| Kev pabcuam kub siab tshaj plaws | ca.1900 ° C |

| Lub ntiajteb txawj nqus tshwj xeeb | ca.3.9-4.1g / cm3 |

| Qhov ntom ntom | ca.1.3-2.0g / cm3 |